|

On-Site repairs

& service

You already

own one of the nicest precision toolroom lathes made in this country,

the Hardinge HLV-H. To order a new lathe will cost you upwards of $50K.

It is well worth the effort and some costs to maintain the lathe to

peak performance.

With this

in mind, consider having Babin Machine Tool, with itís 50+ years of

experience, service your lathe on-site, right on your shop floor.

For instance,

we can change the spindle and motor belts, counter pulley bearings,

and brake cork with adjustments fast. New neoprene carriage way wipers

can be fitted. Youíll probably notice they can get hard and crack

over time and let chips penetrate under the carriage causing premature

bedplate wear. We can refit a tailstock gib and perform alignment checks.

New spindle bearings fitted, cross slide repairs or hand scraping, no

problem.

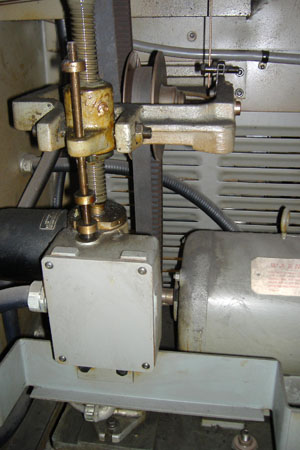

Compound

toolpost slide giving you problems? Send it to us for complete or partial

rebuilding. Apron oil flushed, gibs adjusted, DROs installed, and much

more. Check out our rebuild pages for more pictures.

Invest in

your precision lathe and it will pay for itself very quickly.

|

Home | Products & Services | About Us | Contact Us

Home | Products & Services | About Us | Contact Us

Home | Products & Services | About Us | Contact Us

Home | Products & Services | About Us | Contact Us