|

Rebuild

a Classic!!!

Have your Hardinge HC chucker lathe

rebuilt to new machine "feel" and high quality appearance.

Rebuilding process includes complete disassembly, hand scraping

of gibs and ways, reground dovetail bedplate, new precision spindle

bearings, new turret bearings, professional high gloss paint, refitting

to "like-new" tolerances, and much more.

Hardinge factory still has most parts available for this great production

lathe.

Babin Machine Tool rebuilding customers are located throughout the country.

Click

here for pdf brochure

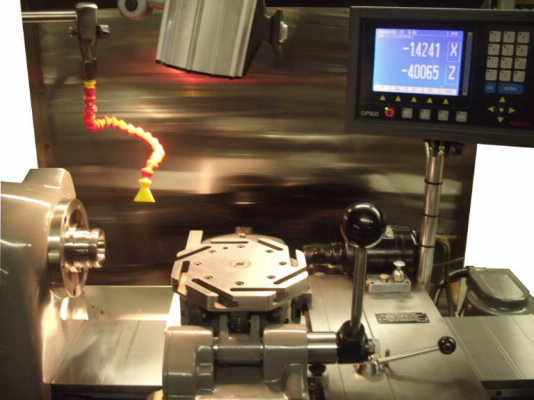

Hardinge HC (1976) chucker rebuilt for

our CT customer. Newall DP900 DRO installed for .0001” resolution

on diameter with 99 tool offsets, 5 year warranty and much more.

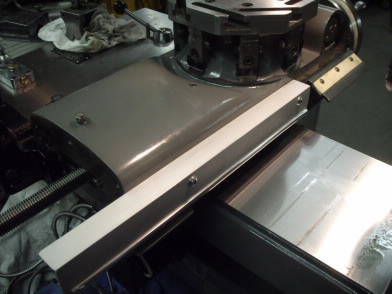

Custom made stainless steel rear chip

and coolant guard has been fitted with rear lifting handles for easy

removal for cleaning.

We can also

retrofit your HC to a CNC/manual version or gang style CNC.

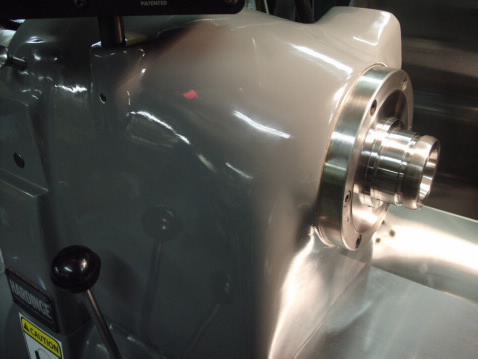

Hardinge headstock

immediately after painting. Comb anyone?

We use high gloss polyurethane paint

with a lot of elbow grease underneath. Optional metallic paint and custom

colors available. Non-painting option as well.

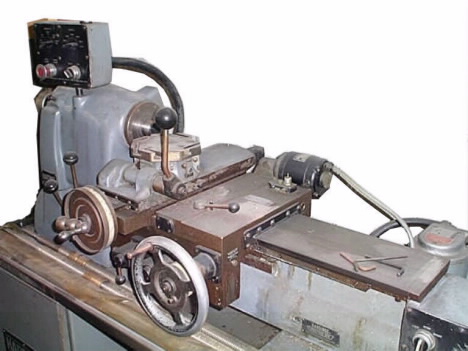

Typical tired “before”

chucker.

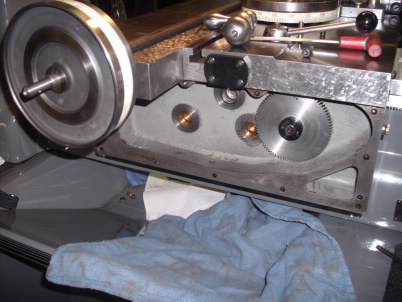

Sometimes we have to check

under the hood.

Almost ready for painting

now that three layers of paint have been removed.

Of course a high build

primer will be laid down first.

Hardinge HC chucker headstock

Background is the easy-to-clean

lift-off stainless chip and coolant guard.

Newall DP900 display rides

with the carriage and features a 5 year warranty.

Not bad for a 30+ year old lathe. Ready for another 30 years of precision

work.

Cross slide DRO scale (covered)

and reader head in place and tested.

We treat your lathe like

our own and we strive for attention to detail.

50 years of satisfied

customers. We know you will be, too.

We perform on-site repairs,

maintenance and service for Hardinge lathes.

We also sell new import

5C Hardinge chucker style lathes. Click

here

|

Home | Products & Services | About Us | Contact Us

Home | Products & Services | About Us | Contact Us

Home | Products & Services | About Us | Contact Us

Home | Products & Services | About Us | Contact Us